Bandstahl-Service-Hagen GmbH is not only an innovative and growth-oriented service center in Hagen, Germany but a reliable and experienced partner for the automobile industry.

Besides the variety of hot-rolled steel strip, stained or unstained and available in all common quality categories, we also produce cold-rolled and surface finished strips. Our products are produced in modern and high-quality cracking plants, operated by highly motivated employees and enhanced by repeatable manufacturing processes. Those processes are subject to strict quality conformance tests in order to meet our customers’ requirements. In addition to that, our corporate policy combines the requirements of quality, environmental, occupational safety and energy policy and we, Bandstahl-Service-Hagen GmbH, adhere to the responsibilities in each of those areas.

Quality, occupational safety, health and environmental protection as well as the careful treatment of resources are a fixed component of our corporate goals and principle that constitutes the basis of every action. The adherence to those principles is essential to the company’s success.

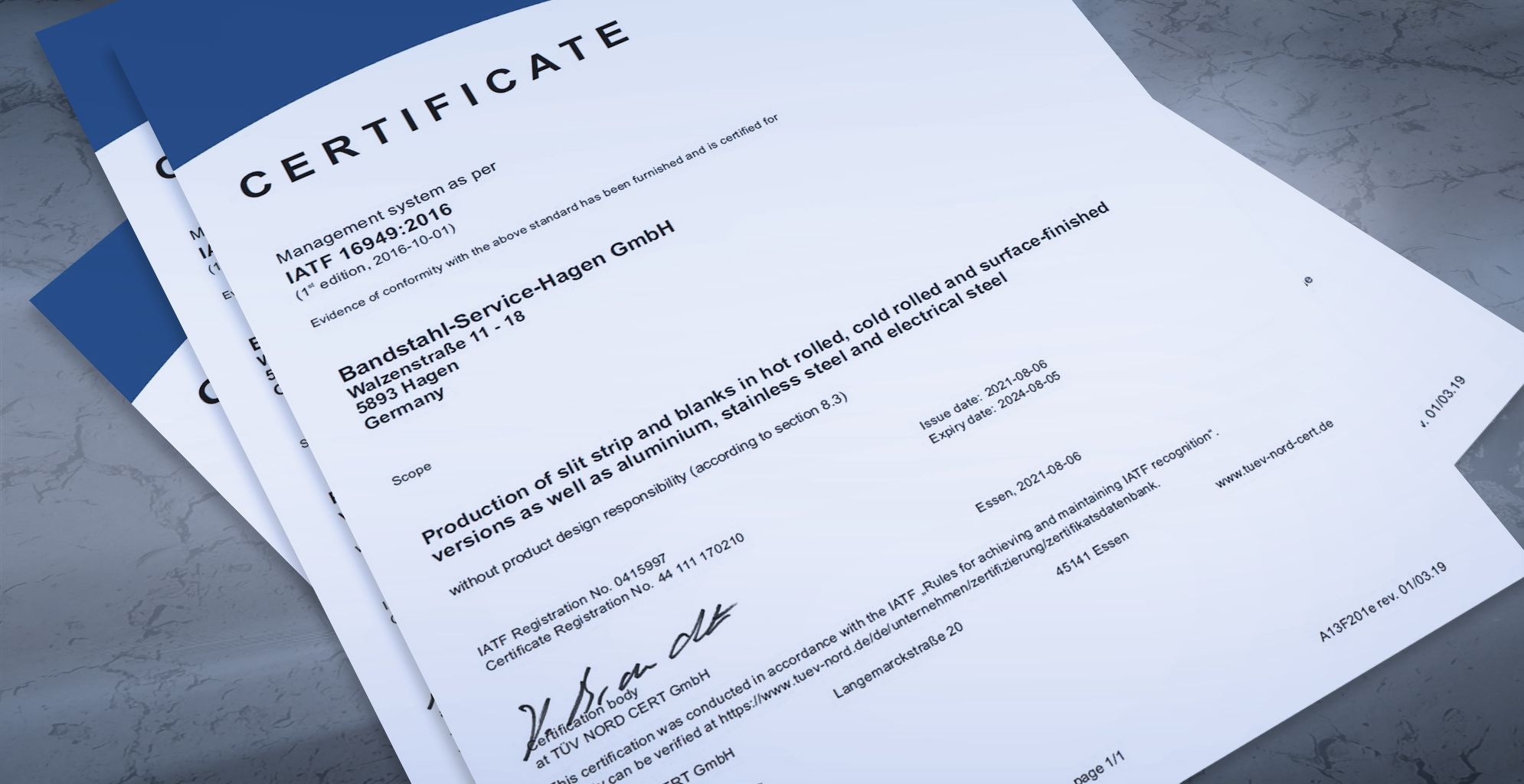

Bandstahl-Service-Hagen GmbH is traditionally eager to provide the most effective and transparent quality management systems. In 2003 we obtained the first certificate under the terms of the former standard DIN EN ISO 9001. As a result, it was only natural to implement further steps to guarantee an efficient quality management system.

Therefore a strong customer focus and intensive communication among our employees are two major parameters for record performances for and with our customers. Since not only our customers from the automobile sector demand high standards, the same principle applies to our customers among the electronics sector or other press, stamp or drawing companies.

The IATF 16949 certification – BSH is well-positioned for the future

Since the IATF 16949 certification is a further milestone for corporate short- and long term success, intensive preparations for the necessary audits, important and non-negligible investments in machines and plants as well as employee training eventually paid off.

“For us, obtaining the certification is the final affirmation for persistent efforts to improve system, process, and product quality,” says CEO Michael Leber, “we are proud to announce that we fully meet the requirements of the IATF 16949 certification.”

The IATF 16949 certification combines the requirements of the former ISO 9001 certification for automobile supplier’s quality management system. The requirements to obtain the certification are based on the default values provided by the International Automotive Task Force (IATF). One of the major norms is not only the debugging within each process but the elimination of errors at earlier stages in order to prevent errors from occurring.

Approximately 30 percent of the automobile manufacturers worldwide joined the requirements of the nine IATF members. Among those members are BMW, Chrysler, Daimler, Fiat, Ford, General Motors, PSA, Renault and Volkswagen.

Despite all adversities in the global economy we, as the corporate management, are positively looking ahead because quality will always prevail.

Quality Assurance

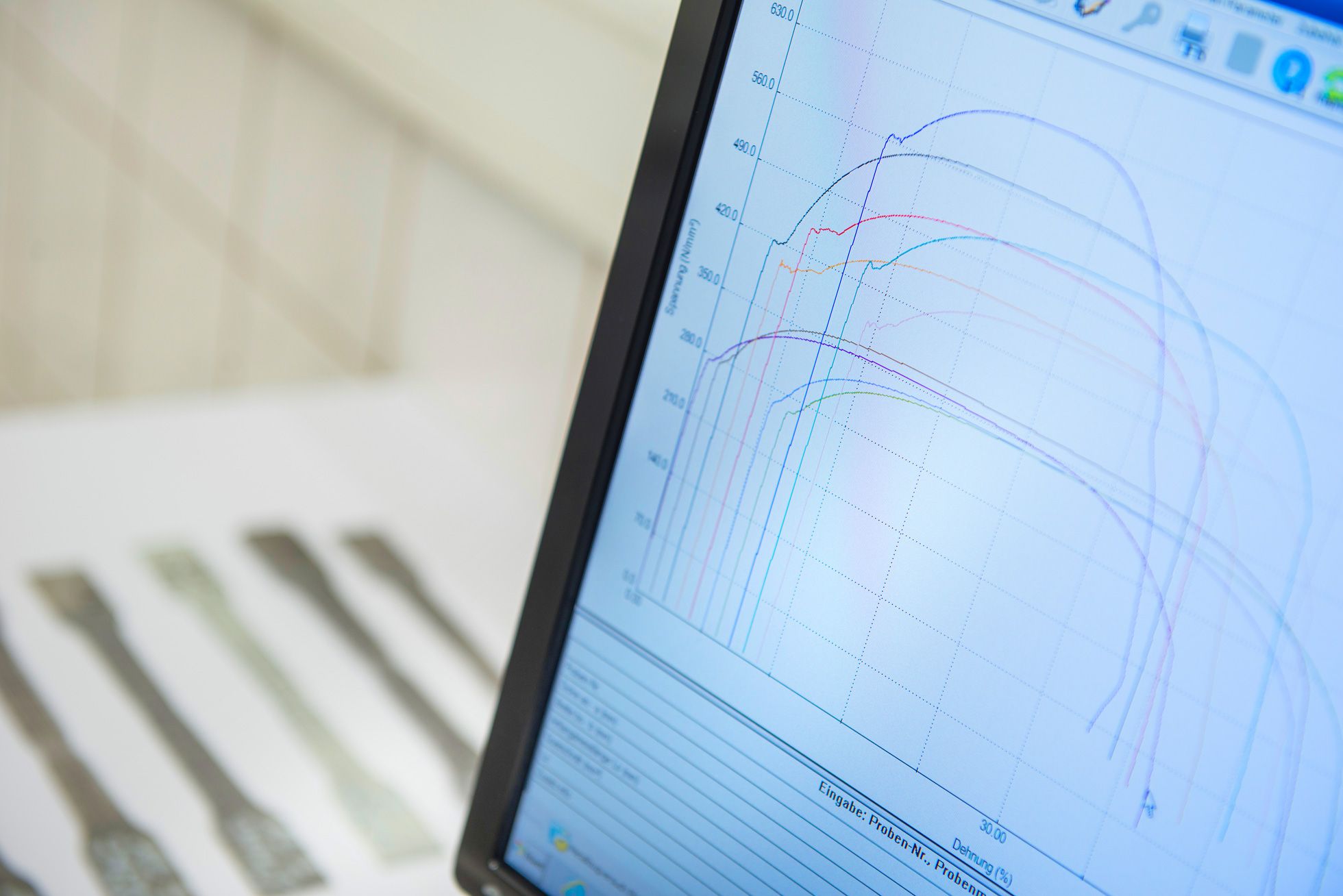

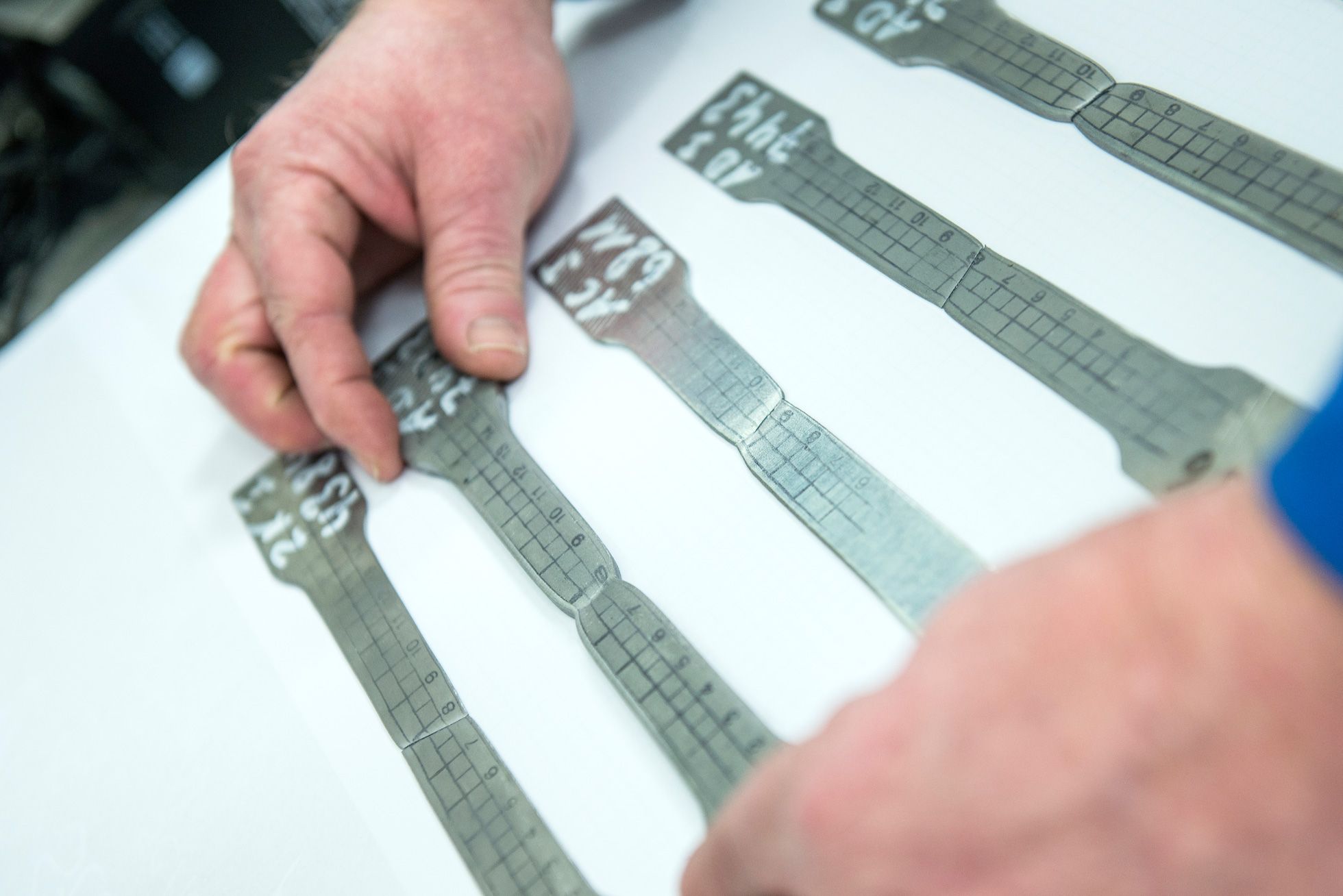

QUASAR Universal Testing Machines – developed for the most challenging demands in labs and industry. They are well suited for performing quasi-static tests.

The load frame has been CAD-engineered. Its rigidity has been optimized using Finite Element Analysis. The machines are produced in series from high-value components procured from renowned German and European manufacturers.

With a design and performance that fulfil the most stringent demands, these machines fulfil and exceed the national and international

requirements placed on quasi-static testing, including a strain rate control in accordance with ISO 6892 (replaces all EN10002) Method A, ASTM E4 etc.

All QUASAR Universal Testing Machines have a LAN port for PC connection, over which they can be operated via Graphwork, the intelligent control and evaluation software.

LabTest is a complete software solution of outstanding performance. Software provider GALDABINI, one of the leading providers in this area, uses its know-how also for controlling automated robotic testing centres. The software provides a selection of over 600 result presets. It goes without saying that operation is intuitive and test procedures are freely programmable. Integrated instructional help videos are available.

As a new feature, optional video recordings of tests can be captured in real time for documentation and other purposes.

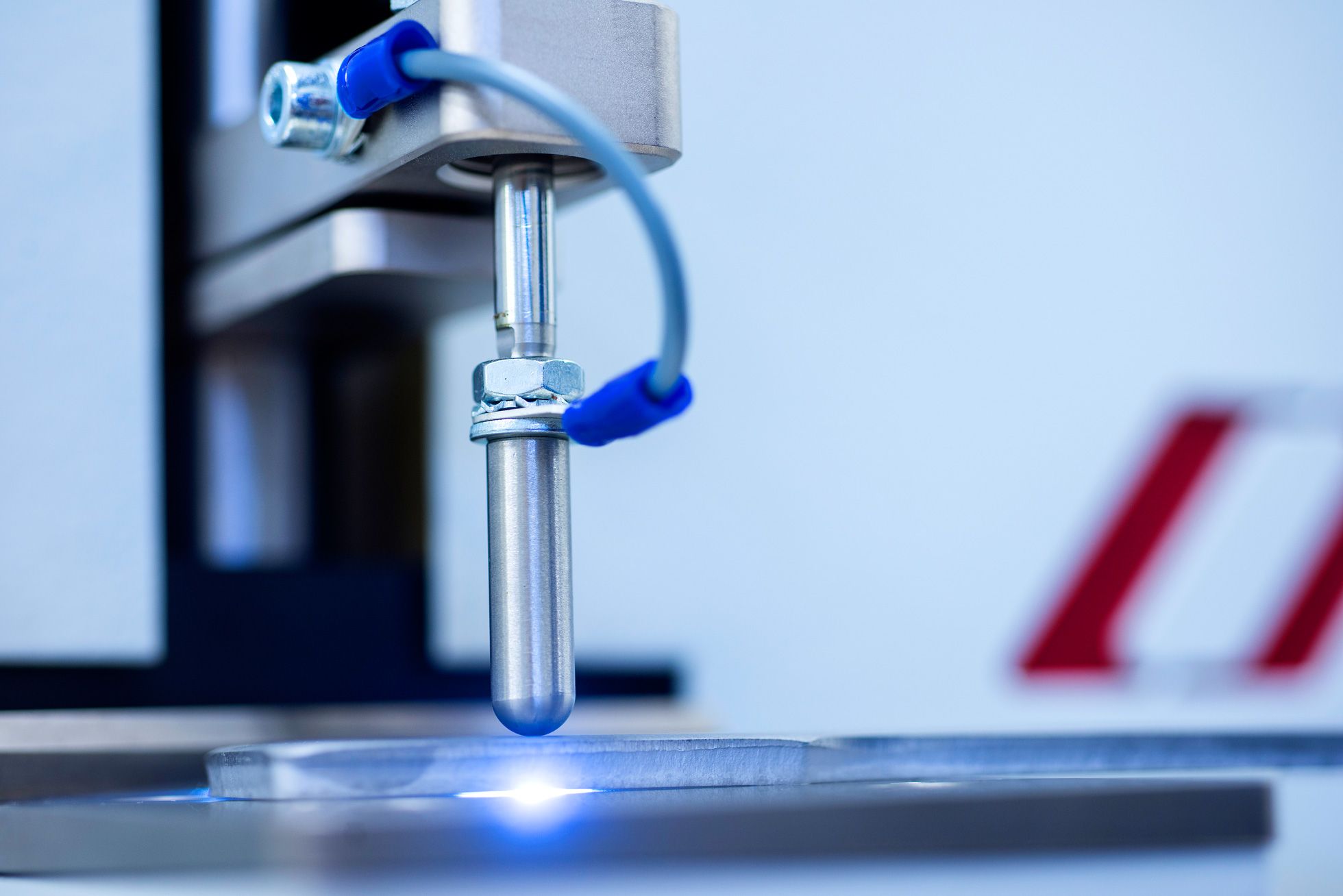

OBLF GS 1000-II analysis instrument for high-precision metal analysis

Simultaneously measuring optical vacuum emission spectrometer for the quantitative analysis of mass proportions in metals and alloys. The instrument makes no compromises in function and design and corresponds to the latest technical standard. Its integrated OBLF control computer works together with an industry-standard PC to provide for further data processing.

The spectrometer system is equipped with a patented self-cleaning spark stand, eliminating the need for permanent argon supply which is a characteristic of conventional spectrometers. Since no argon flows during “standby operation”, argon consumption is reduced drastically. The short analysis time, achieved with the help of the excitation generator’s 1kHz spark sequence frequency, also contributes towards minimizing argon consumption.

The system’s integrated stabilizers guarantee a superior long-time stability independently of the installation site.